How To Calculate Cost Of Goods Manufactured - The Full Guide

A primary element in accounting, the cost of goods measured can be a complicated equation to calculate, particularly if you are a small business with limited resources and no personal accountant.

When running a business, it is important to have an in-depth working knowledge of the components. This allows you to make informed decisions regarding the company’s future, and properly take note of successes, failures, and unforeseen overheads.

This article will hopefully go some way to explain what cost of goods measured actually is, why it is important to business, and how you can easily calculate it to ensure you are getting the most you can from your business’ output.

Also read: Find Retained Earnings

What is COGM?

Cost of goods measured (or COGM) is a calculation used to determine a company’s success. This is done by calculating the outgoings against the income over a specific financial period, taking into account all parts of the manufacturing process that take the core components to the finished product.

This can help business owners ascertain whether the cost of production is financially viable when put against their income from sale.

If the answer is “yes”, then the company is working efficiently, but if the answer is “no”, then some alterations will need to be made.

This could be as simple as using cheaper production materials, reevaluating the size of the workforce, or in extreme cases, even outsourcing production altogether.

Also read: What Are Assets, Liability, and Equity?

What Affects COGM?

Within the manufacturing process, there are several things that can lead to a negative COGM.

Expensive Materials

Firstly, if the cost of the core components are too high when compared to the income from the finished product, then some changes will need to be made.

This could include research into cheaper alternatives, finding experimental materials, or looking for companies who can provide them at a cheaper price.

This correlates directly with the price of the specific finished product. Take for example a cashmere sweater. When compared to a normal type of wool, cashmere is better quality, has a higher thread count, and is more expensive to purchase as a result.

Because of this, the sweater has to be sold at a higher price when it reaches the market, so as the company can make a profit.

If the company was to sell the sweater at a cheaper price whilst still buying the expensive cashmere, then they would hemorrhage money in no time at all.

Also read: How To Prepare Your Accounts For New Hires

Production

The cost of hiring staff for a production line can be particularly expensive, which is why many companies choose to outsource their production to other countries, often where the rates of pay are notably cheaper.

Whilst unethical, it is a large and common occurrence within the manufacturing industry, with many companies opting for outsourced production in developing countries to dramatically cut the costs.

Workforce

Another common occurrence in the manufacturing industry is the reevaluation of the workforce.

This happens in a lot of workforces, but the manufacturing industry is perhaps the most prevalent. When profits are low, companies will seek to increase their revenue by firing unnecessary employees from their ranks.

This could be done by examining every aspect of the process to see where inefficiency lies, or it could be done more brutally, resulting in mass redundancies.

Also read: 12 Best Finance Podcasts For Your Savings

Property Rent

The rent companies pay on their warehouses is also a factor in their overall turnover.

Expensive rent can lead to financial losses, whilst cheaper rent can make profits easier to attain and financial success a possibility.

How To Calculate COGM?

When calculating the cost of goods manufactured, you need to factor in the cost of direct materials, the cost of direct labor, and the manufacturing overhead to get the overall figure.

Once you have that figure, you need to add the beginning work in process, and subtract the ending work in process from the overall cost of manufacturing to get the cost of goods manufactured.

As you can imagine, this can be a complicated and difficult process, particularly in companies with multiple interests and departments. As such, the COGM schedule was designed to help expedite the process and make it easier for businesses to work it out.

This can be simplified in the below equation:

COGM = Beginning of work in process inventory + total manufacturing cost - ending of work in process inventory

Why Is COGM Important?

Cost of goods manufactured is incredibly important to the overall financial running of the company, as it allows company bosses to effectively break down the components of the production process, and lets them see the successes, the losses, and any dead wood that needs to be cut from the company.

It also adds to the overall clarity of the company, allowing for greater organization from the bottom up. It directly influences the price of goods and services, informs sales plans going forward, and allows an accurate comparison from year to year, so they can strategize accordingly.

COGM Vs COGS

Whilst COGM refers to the cost of goods manufactured, COGS refers to the cost of goods sold.

Cost of goods sold is the amount of money the company spends on labor, materials, and unforeseen expenses.

Once the finished products are sold, the cost of goods sold can be properly worked out ready to move forward.

Also read: 11 Best Personal Finance Books

Final Thoughts

Financial calculations in all aspects of business can be tricky without the proper know how and expertise.

This kind of knowledge and independence are what can make the prospect of self employment daunting to some people, and the improper balancing of the above equations are responsible for the high number of businesses failing each year.

The important things to take away are clarity, organization, market research, and the development of a frank and just working practice that can assess successes and failings without prejudice, and help to properly manage the costs of labor and production against the finished products and their income.

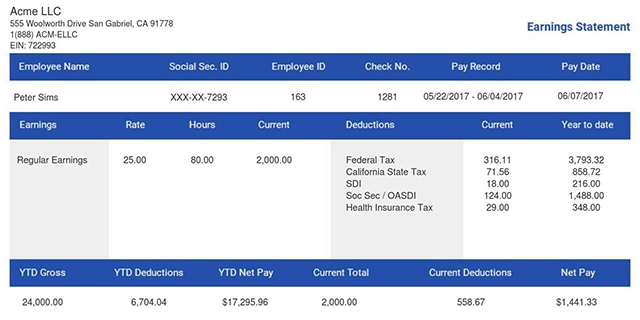

If you haven't got the most efficient way to produce pay stubs for your employees, check out the pay stub maker today. It is so easy and convenient!